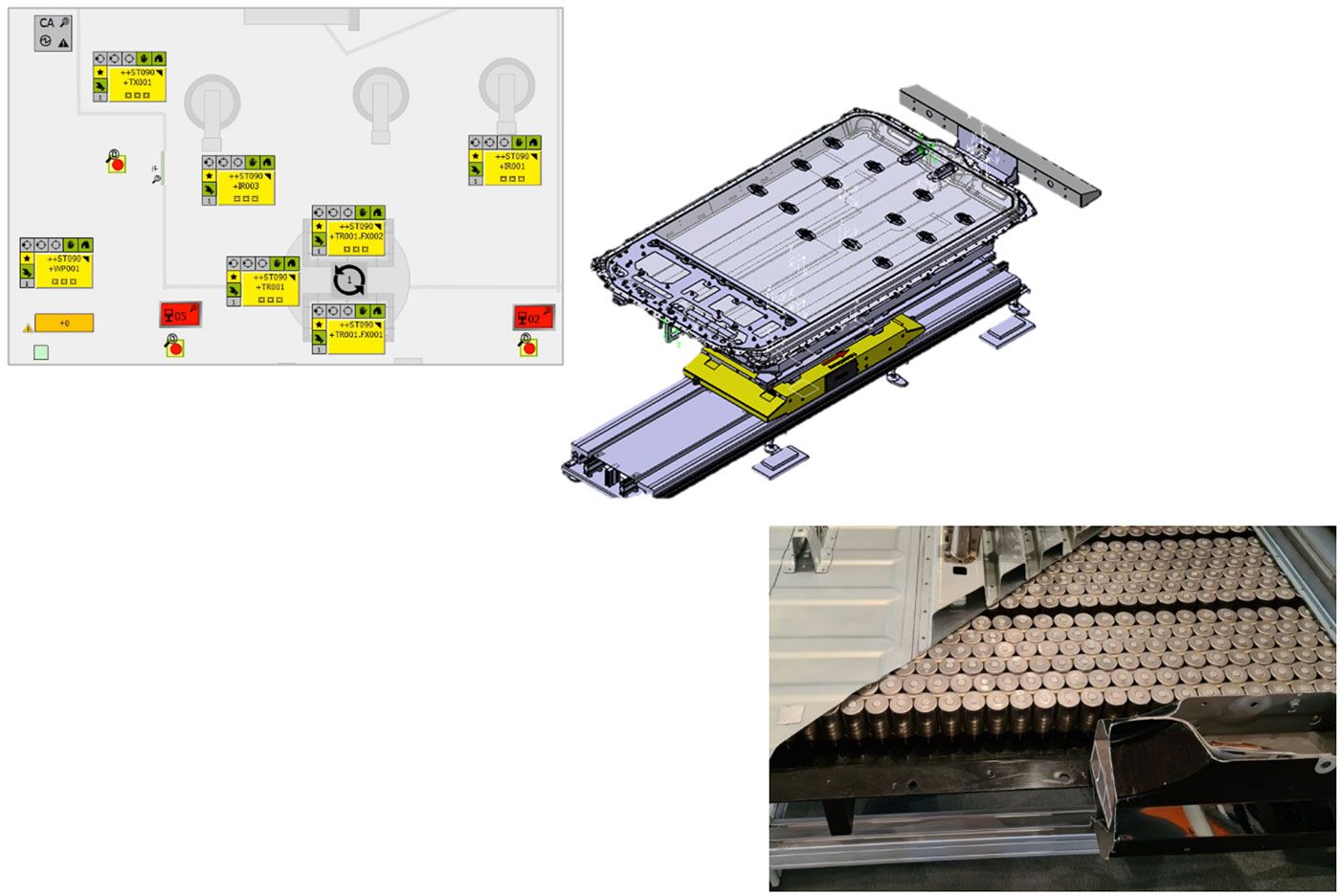

Energy module GEN6 GSC: technology EM – NCAR (new installations)

Date: 2023 to 2025

Contracting entity: BMW – plant engineering

End customer/site of installation: BMW Hungary (W15)

Project description:

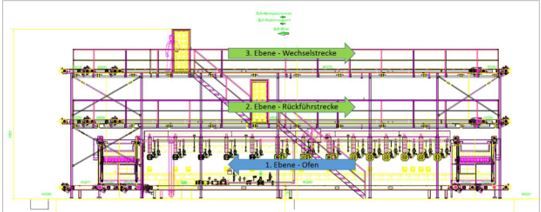

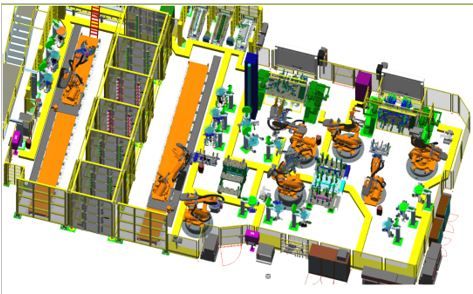

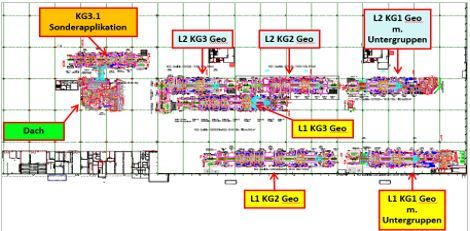

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

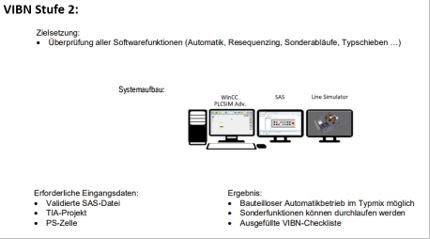

- Virtual commissioning, physical system start-up

Technologies (excerpt):

21 pieces S7-1500 with CPU 1518F – PN/DP | 21 pieces OC visualization with WinCC Unified on Beckhoff CP3224 | 51 pieces OP visualization with WinCC Unified on Beckhoff CP3224 | 95 pieces KUKA KR C5 industrial robots