Successful Automation Projects in Industry and Manufacturing

References say more than a thousand words. The names of our customers are synonymous with the personal relationships that have grown over time among all project participants. This is just one reason why we, an established company for industrial control and automation technology, to this day are a trusted partner for many industries.

Our projects – technical details, here we go!

Date: ongoing

Contracting entity: ERS – Elektrotechnik

End customer/site of installation: BMW Group, Research & Innovation Centre (FIZ)

Project description:

We continuously maintain and expand the monitoring control systems of the data center to permanently record and evaluate various measurement signals (temporary I/Os, currents). For this, we use various PLC controls, which are centrally visualized via WinCC. An ACC system displays the operating status and triggers an alarm if necessary. In addition, energy consumption is measured and evaluated. Recirculating air-cooling units are centrally controlled for each smoke section. The control system provides the IT equipment with constant cooling while consuming as little energy as possible.

Technologies (excerpt):

≈ 40 pieces Siemens S7-300 controllers in various designs | 1 Comfort Panel TP2200 | ≈ 10 pieces Touch Panels TP177B/A | WinCC Advanced V17 | WinCC flexible 2008 | Step7 V5.5 | WinCC V7.x

Date: ongoing

Contracting entity: BMW Group

End customer/site of installation: BMW Group Research & Innovation Centre (FIZ)

Project description:

We are continuously renovating, maintaining, and expanding the existing lighting and blind control systems and adapting them to current requirements. A central control system bundles the building management technology in the control center so that all external systems are supplied with commands and monitored. A visualization allows for carrying out switch-on and switch-off commands, which can be adjusted individually per building/floor if required.

Technologies (excerpt):

> 50 pieces Siemens S7-300 controllers | > 300 pieces WAGO I/O PROFIBUS connections 750-xxx | ≈ 10 pieces Vipa small controllers 200V series | 2 pieces Siemens 319F/1516F | 1 Comfort Panel TP2200 | ≈ 30 pieces TP177B/A touch panels | > 200 pieces WAGO controllers | KNX controllers | WinCC Advanced V17 | TIA V17 | WinCC flexible 2008 | Step7 V5. 5 | WAGO lighting management software | WAGO core distributor software | KNX ETS5

Date: 2025

Contracting entity: Technical University of Munich (TUM)

Project description:

We took over the control software (existing system in a laboratory environment) for an electrolysis test rig and continued programming according to the specifications and planning status. In doing so, we implemented the start, operating, and shutdown behavior, including standard alarms and emergency stops. The system is operated and monitored via PRISMA, and individual units can be controlled by hand. Interdependencies between pumps, blowers, heaters, and rectifiers ensure safe operation. The system is used to record measurement series for electrolysis via a catalyst.

Technologies (excerpt):

Siemens SPS | PRISMA | EPLAN | Shutdowns via safe contactors and STO functions | Analog and digital I/O | Industrial sensor technology

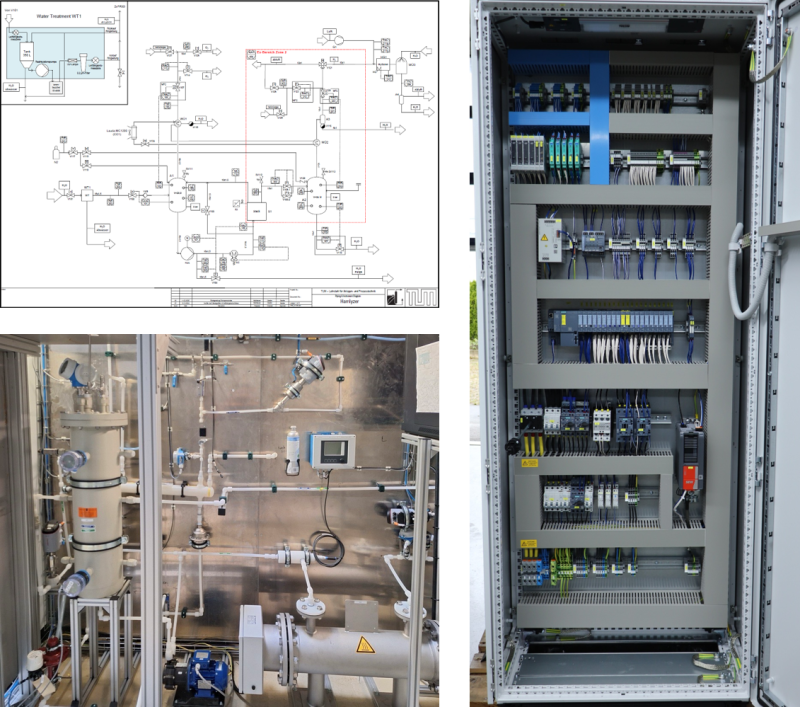

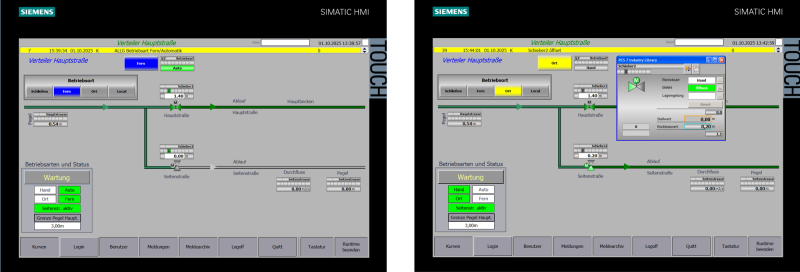

Date: 2025

Contracting entity: City of Munich, municipal drainage works Munich

Project description:

The distribution facility regulates the flow of wastewater from western Munich to the sewage treatment plants Munich North and Munich Gut Marienhof. Thanks to the new digital data connection, signals for controlling the valves as well as the feedback are transmitted in real time between the distribution facility and the control center. We supplied, installed, and programmed the control technology and carried out the commissioning.

Technologies (excerpt):

PROFINET valve controls | CPU S7-1512F | Visualization Simatic PC 477 | TIA V20 | WinCC Advanced

Date: 2024 to 205

Contracting entity: BMW Group

End customer/site of installation: BMW Welt

Project description:

We updated the control technology of the high-bay warehouse from PROFIBUS and S7-400 to the TMO-V3 standard with PROFINET and S7-1500. New control cabinets, subdistribution boards, and control panels were manufactured and installed. A new PC-based warehouse management system was integrated, which communicates with the BMW merchandise management software. In addition, we connected the media technology for the visitor tour, and carried out virtual and real commissioning.

Technologies (excerpt):

SPS 1518F – PN/DP | Beckhoff 24" control panels | Mobile panels for RBG operation | MOVIDRIVE C Modular for RBG control

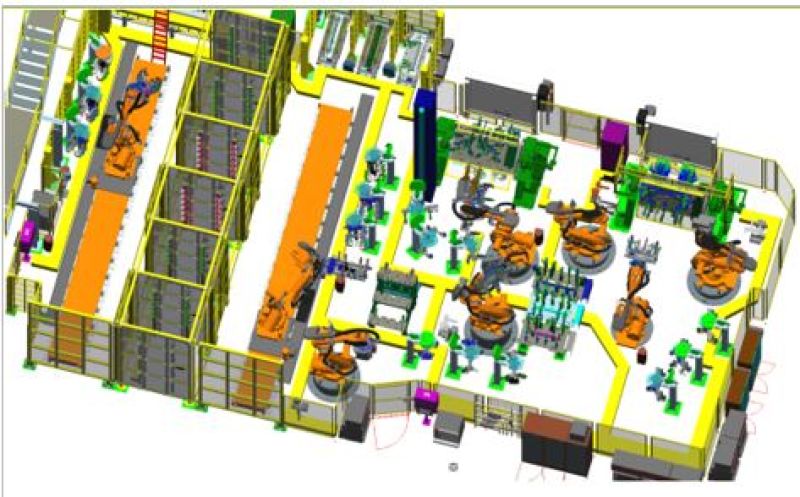

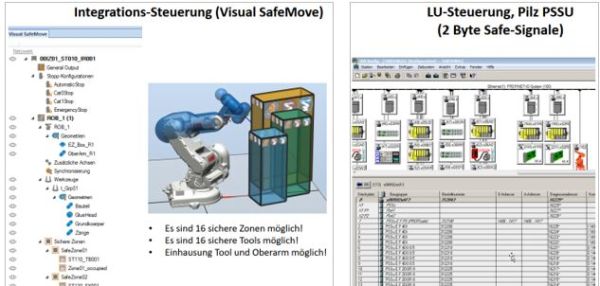

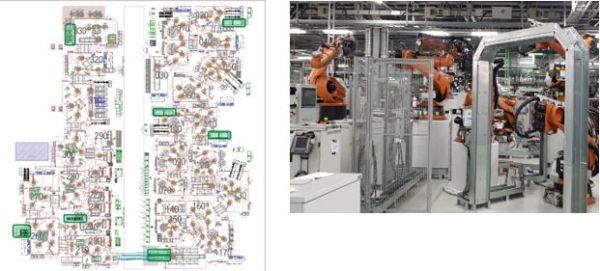

Date: 2023 to 2025

Contracting entity: BMW – plant engineering

End customer/site of installation: BMW Hungary (W15)

Project description:

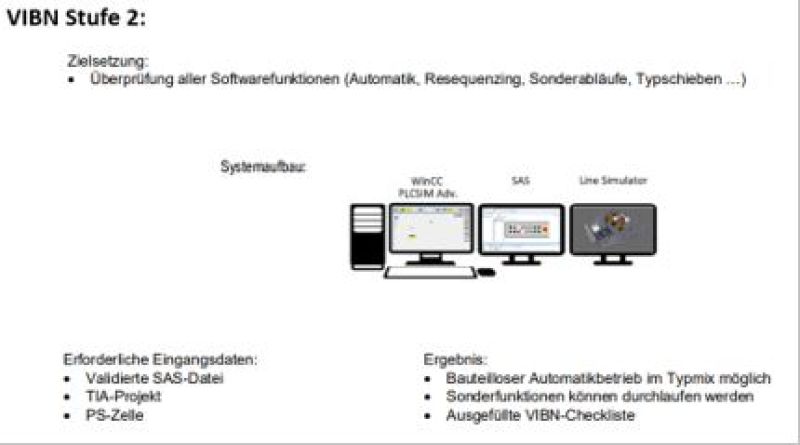

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Virtual commissioning, physical system start-up

Technologies (excerpt):

21 pieces S7-1500 with CPU 1518F – PN/DP | 21 pieces OC visualization with WinCC Unified on Beckhoff CP3224 | 51 pieces OP visualization with WinCC Unified on Beckhoff CP3224 | 95 pieces KUKA KR C5 industrial robots

Date: 2023 to 2025

Contracting entity: HORIBA Europe GmbH

End customer/site of installation: BMW Aschheim

Project description:

In the course of the new construction of six chassis dynamometers, we received the partial order to develop a new human interface and the visualization. The operating concept, which had become outdated, was to be renewed and converted to a modern concept with a promising future. The human interface is used for the central control and visualization of each test rig. In the first step of the project, seven human interfaces are built; in the second step, another nine are built and delivered. Visualization takes place via a server-client system with WinCC Unified V18.

- Planning (hardware construction, software project planning)

- Control cabinet construction

- Supply of new subdistribution boards, control cabinets, and human interfaces

- Assembly and installation

Technologies (excerpt):

16 pieces subdistribution boards/cabinets with S7-1516F/S7-1515F CPU | 16 pieces human interfaces with ET200SP | WinCC Unified V18 | TIA V18

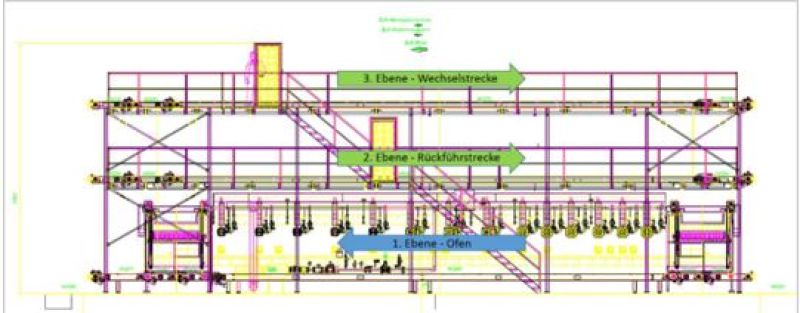

Date: 2023 to 2024

Contracting entity: BMW Group

End customer/site of installation: BMW Dingolfing

Plants such as:

WU292/oven (refurbishment) | WU292/press (refurbishment) | WU293/oven (refurbishment) | WU293/press (refurbishment)

Project description:

Car body parts are hardened on two identical systems WU292 and WU293. For this purpose, the cold-pressed components are heated in a continuous furnace and systematically cooled in a tool in the press. Measures to maintain the substance of the electrical components of the conveyor lines are being carried out at both plants. For this, cables and components are renewed, parts are brought up to date and recommissioned.

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction, air conditioning, and SEW inverter adjustment

- Provision of burner control units

Technologies (excerpt):

8 pieces S7-400 with CPU 416 | 8 pieces visualization Zenon 7.60 | 56 pieces burner control units | 20 pieces Rittal cooling systems Blue e+ | 60 pieces SEW inverters on MOVI-PLC

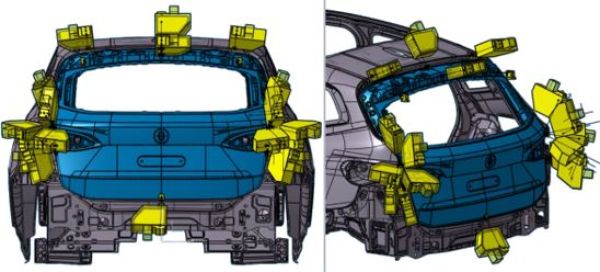

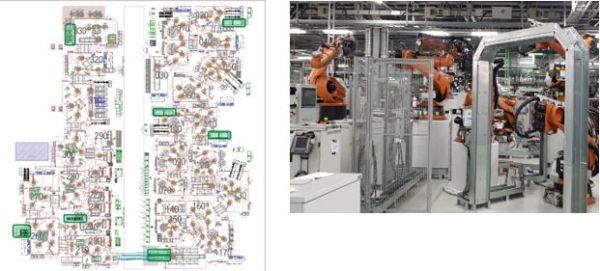

Date: 2023 to 2024

Contracting entity: TMS Turnkey Manufacturing Solutions GmbH

End customer/site of installation: BMW Dingolfing

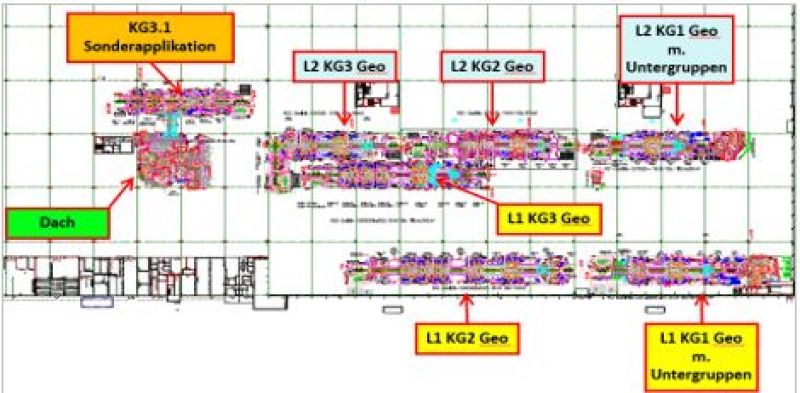

Plants such as:

KG1 (integration) I KG2 (integration) I KG3 (integration) I KG3 welding (integration) | SR inside (integration) I SR middle (Integration) I SR outside (integration)

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Virtual commissioning, physical system start-up

Technologies (excerpt):

18 pieces S7-1500 with CPU 1518F – PN/DP | 18 pieces visualization with WinCC on PC 677 | 35 pieces visualization with WinCC on PC 477E | 70 pieces control units with WinCC visualization | 76 pieces KUKA KR C4 industrial robots in the range of body carcasses | 60 pieces KUKA KR C4 industrial robots in the range of side frames

Date: 2023 to 2024

Contracting entity: DS Automotion GmbH

End customer/site of installation: BMW Spartanburg (USA)

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Supply of new subdistribution boards and human interfaces

- Assembly and installation

- Software and commissioning

- Disassembly of the existing system

In the course of an expansion of the final assembly, the existing plant had to be moved and expanded. The AGVS was moved in several steps and expanded according to construction progress. In addition, the general contractor also delivered other vehicles that we provided. New cabinets were built and installed to meet the increased power requirements, visualization was created on new panels, and the software was adapted and put into operation according to the step and course guidance. Our scope included the complete disassembly and reassembly of electrical components.

Technologies (excerpt):

S7-1500 with CPU 1518F – PN/DP | OC visualization with WinCC-TIA on Beckhoff CP3224 | OP visualization with WinCC-TIA on Beckhoff CP3224 | Vahle technology version | SEW drives | Siemens ET200SP and ET200Pro I/O modules

Date: 2019 to 2024

Contracting entity: BMW – plant engineering

End customer/site of installation: BMW Dingolfing

Plants such as:

G60 – KG1, KG2, KG3, KG-AS, HFR, WL I G60 – SR inside, middle, outside I G61 – KG1, KG2, KG3, KG-AS, HFR, WL I G61 – SR inside, middle, outside I G32 – SR inside, middle, outside I G6x – roof system

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Virtual commissioning, physical system start-up

Technologies (excerpt):

40 pieces S7-1500 with CPU 1518F – PN/DP | 40 pieces visualization with WinCC on PC 677 | 80 pieces visualization with WinCC on PC 477E | 100 pieces control units with WinCC visualization | 244 pieces KUKA KR C4 industrial robots in the range of body carcasses | 156 pieces KUKA KR C4 industrial robots in the range of side frames

Date: 2023 to 2024

Contracting entity: DS Automotion GmbH

End customer/site of installation: AGCO Fendt – Marktoberdorf

Project description:

- Entire electric planning (hardware construction, software project planning)

- Extension of control cabinet construction

- Provision of control technology for the extension works

- Assembly and installation

- System commissioning

Technologies (excerpt):

S7-414F-3PN/DP | 4 pieces MP277 10" TOUCH | 10 pieces access points for Wi-Fi coverage (communication with vehicles) | 30 pieces vehicles for transport and setup of the tractors (combustion engines and e-tractors)

Process description:

The assembly line was adapted for the integration of the new electric vehicle (E124P series) into the final assembly of tractors in Marktoberdorf. The automated guided vehicle system (AGVS) ejects the vehicles with bodies for electric tractors from the existing production line so that high-voltage assembly and testing processes can be carried out in a new, separate hall area before they are returned to the production line.

The central control system developed by Kocher for the AVGS carries out not only the data management with the hall control system of the end customer (order data to error messages), but also all process-relevant orders of the vehicles through the processing stations. With its own Wi-Fi communication, it is the centerpiece of the workflow and controls the process throughout the entire production line for all station control points.

Entries can be made via a visualization interface to adjust parameters, select/deselect processes, and display processes, vehicle positions, interface overviews, and error messages. In addition to the standard process sequences, emergency strategy concepts are implemented according to individual requirements.

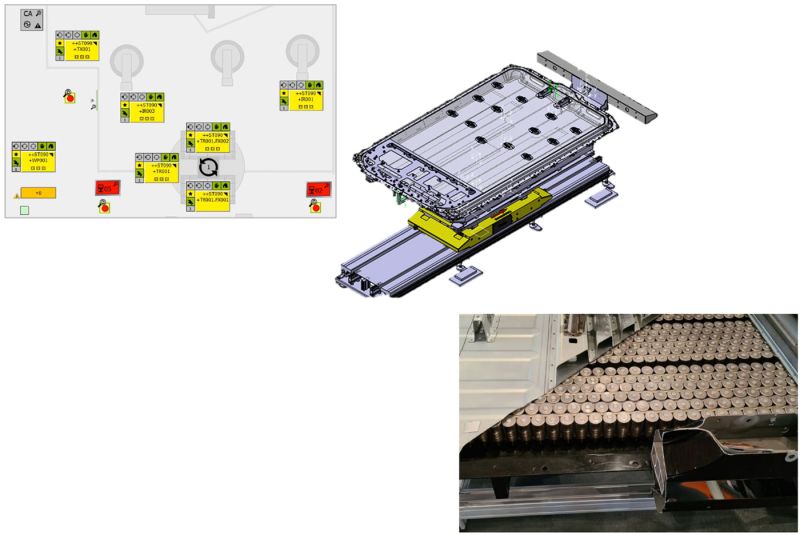

Date: Projects from 2020 to 2024

Contracting entity: DS Automotion GmbH

End customer/site of installation: BMW Dingolfing (W2.20)

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Project-dependent: virtual commissioning, physical system start-up

Technologies (excerpt):

2 pieces S7-1500 with CPU 1518F – PN/DP | OC visualization and OP visualization with WinCC TIA V14 on Siemens PC-677D and Beckhoff CP3224-2003-0020 | 11 pieces access points for Wi-Fi coverage (communication with vehicles) | 68 pieces vehicles for the transport and assembly of the high-voltage storage systems | 64 pieces vehicles with lifting and swiveling unit for the transport and assembly of the high-voltage storage systems

Process description:

The central control system developed by Kocher for the automated guided vehicle system (AVGS) carries out not only the data management with the hall control system of the end customer (from order data preview to error messages), but also all process-relevant orders of the vehicles via robot cells and manual processing stations. With its own Wi-Fi structure, it is the centerpiece of the workflow and controls the process throughout the entire production line for all station control points.

Entries can be made via a visualization interface to adjust parameters, select/deselect processes, and display processes, vehicle positions, interface overviews, and error messages. In addition to the standard process sequences, emergency strategy concepts are implemented according to individual requirements.

- Date: 2021 to 2023

- Contracting entity: BMW – plant engineering

- End customer/site of installation: BMW Regensburg

Plants such as:

KG1, KG1-AS, WL, HFR (integration) I KG2, KG2-AS (integration) I KG3, KG3-AS (integration) I Roof system (integration) | Front flap (new system) I Measuring cells GOM (new system)

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Commissioning

Technologies (excerpt):

28 pieces S7-400 with CPU 416 | 28 pieces visualization with Zenon on PC 627 | 40 pieces control units with Zenon visualization | 235 pieces ABB IRC5 industrial robots (integration)

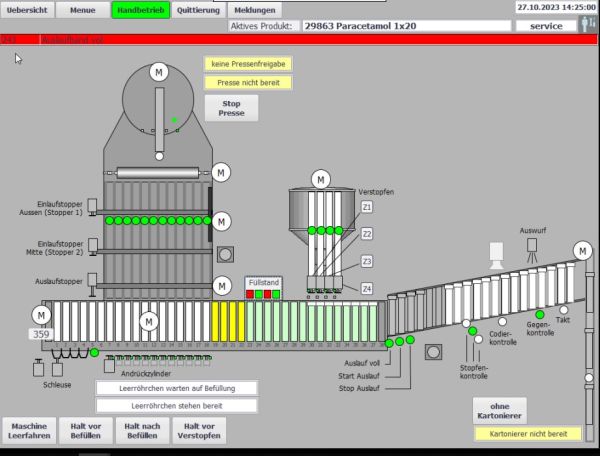

Date: 2023

Contracting entity: HERMES ARZNEIMITTEL GmbH

Project description:

- Planning (hardware construction, software project planning)

- Control cabinet construction

- Supply of new subdistribution board, control cabinet, and human interface

- Assembly and installation

- System commissioning

Technologies (excerpt):

S/-1500 with CPU 1511F-1 PN | Visualization on ASEM PC HT3500 | SEW frequency converter MCX91A

Date: 2022 to 2023

Contracting entity: ICT

End customer/site of installation: BMW Spartanburg (USA)

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Supply of new subdistribution boards, control cabinets, and human interfaces

- Assembly and installation

- Software and commissioning

- Disassembly of old chargers

The final work on the production cars is carried out in an existing finishing line. To ensure that the 12VDC battery does not run down, it is possible to use external chargers to maintain the capacity or recharge the battery. The existing system had to be adapted due to a new vehicle type. In the course of this work, the battery-charging concept was completely revised. Due to a new EMS system that was installed above the production line, the battery chargers could be delivered to the worker in sync with the car. A new control system was installed, which communicates with the carriers via a CAN bus and tracks them with millimeter precision using a barcode positioning system. The track (approx. 300 m) includes several switches and a repair track with maintenance jack. After successful implementation, the old battery technology was dismantled.

Technologies (excerpt):

S7-1500 with CPU 1518F – PN/DP | OC and OP visualization with WinCC-TIA on Beckhoff CP3224 | Vahle technology version | SEW drives | Siemens ET200SP and ET200Pro I/O modules

Date: 2022 to 2023

Contracting entity: MBN Maschinenbaubetriebe Neugersdorf GmbH

End customer/site of installation: BMW Spartanburg (USA)

Project description:

- Electric planning (hardware and software project planning)

- Disassembly and installation

- Software and commissioning

- Robot programming

- Disassembly of a system

Due to the discontinuation of a model and the introduction of a new type, the marriage had to be adjusted in the final assembly. As one of the existing systems was no longer needed, it was removed from the control system and uninstalled. In return, a new type was integrated into the remaining systems. This resulted in completely new procedures for the robots, screwdrivers, and in the process, among other things. Over the course of the years, the existing systems had been incorporated with a wide variety of standards and technologies and had to be individually adapted.

Technologies (excerpt):

S7-1500 with CPU 1518F – PN/DP | S7-400 | WinCC TIA with PCs, TPs | Various robots

Date: 2022 to 2023

Contracting entity: Esypro

End customer/site of installation: BMW Dingolfing W02.10

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Virtual commissioning, physical system start-up

A conveyor system was installed to supply the wishbones and tie bars to the axis production assembly line. The components are hooked into workpiece carriers according to type in batch sizes at two feeding points and stored by variety in approx. 60 storage lanes. According to the current sequence, the production control system issues a call-up, whereby the components are retrieved from the storage in sequence and transported to the assembly stations via an intermediate level using lifts. After removal, the empty workpiece carriers are conveyed back to the feed stations. Data handling is realized via RFID data carriers and barcodes.

Technologies (excerpt):

S7-1500 with CPU 1518F – PN/DP | OC visualization with WinCC-TIA on Beckhoff CP3224 | SEW MOVIFIT technology version | Murr MVK I/O modules | Siemens ET200SP and ET200Pro I/O modules | Automatic barcode reader and hand scanner

Date: 2019 to 2022

Contracting entity: BMW – plant engineering

End customer/site of installation: BMW Munich

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Virtual commissioning, physical system start-up

Technologies (excerpt):

14 pieces S7-1500 with CPU 1518F – PN/DP | 14 pieces visualization with WinCC on PC 677 | 33 pieces visualization with WinCC on PC 477E | 15 pieces control units with WinCC visualization | 130 pieces ABB IRC5 industrial robots

Date: 2019 to 2022

Contracting entity: BMW – plant engineering

End customer/site of installation: BMW Dingolfing

Plants such as:

KG1 (integration) I KG2 (integration) I KG3 (integration) I KG3 welding (integration) | SR inside (integration) I SR middle (new systems) I SR outside (new systems)

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Virtual commissioning, physical system start-up

Technologies (excerpt):

18 pieces S7-1500 with CPU 1518F – PN/DP | 18 pieces visualization with WinCC on PC 677 | 35 pieces visualization with WinCC on PC 477E | 70 pieces control units with WinCC visualization | 76 pieces KUKA KR C4 industrial robots in the range of body carcasses | 60 pieces KUKA KR C4 industrial robots in the range of side frames

Date: 2019 to 2021

Contracting entity: BMW – plant engineering

End customer/site of installation: BMW Regensburg

Plants such as:

KG1, KG1-AS, WL, HFR (integration) I KG2, KG2-AS (integration) I KG3, KG3-AS (integration) I Roof system (integration) | Front flap (new system) I Measuring cells GOM (new system)

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Commissioning

Technologies (excerpt):

30 pieces S7-400 with CPU 416 | 30 pieces visualization with Zenon on PC 627 | 50 pieces control units with Zenon visualization | 250 pieces ABB IRC5 industrial robots (integration)

Date: 2019 to 2021

Contracting entity: BMW – plant engineering

End customer/site of installation: BMW Leipzig

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Commissioning

Technologies (excerpt):

8 pieces S7-1500 with CPU 1518F – PN/DP | 8 pieces visualization with WinCC on PC 677 | 22 pieces control units with WinCC visualization | 53 pieces FANUC industrial robots

The scope also comprises the complete BestFit system, including hardware, software, engineering, and commissioning.

Date: 2019 to 2020

Contracting entity: BMW – plant engineering

End customer/site of installation: BMW Dingolfing

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Virtual commissioning, physical system start-up

Technologies (excerpt):

5 pieces S7-1500 with CPU 1518F – PN/DP | 5 pieces visualization with WinCC on PC 677 | 9 pieces visualization with WinCC on PC 477E | 24 pieces control units with WinCC visualization | 39 pieces KUKA IR C5 industrial robots

- Datum: 2018 to 2019

- Contracting entity: Emil Bucher GmbH

- End customer/site of installation: BMW Dingolfing

Plants such as:

ZB left wheel housing | ZB right wheel housing | ZB front wall | Entire front end

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Commissioning

Technologies (excerpt):

9 pieces S7-1500 with CPU 1518F – PN/DP | 9 pieces visualization with WinCC on PC 677D | 18 pieces visualization with WinCC on PC 477E | 14 pieces application PC677D | 35 pieces control units with WinCC visualization | 102 pieces KUKA KR C2/C4 industrial robots

- Date: 2017 to 2018

- Contracting entity: Emil Bucher GmbH

- End customer/site of installation: BMW Leipzig

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Robot programming

- Commissioning

Technologies (excerpt):

2 pieces S7-1500 with CPU 1518F – PN/DP | 4 pieces visualization with WinCC on PC 677 | 5 pieces control units with WinCC visualization | 20 pieces FANUC industrial robots

- Date: 2016 to 2018

- Contracting entity/end customer: Emil Bucher GmbH

Project description:

- New test rigs for electric hand tools were designed electrically, the associated software was created individually, while existing test rigs were optimized specifically to meet current requirements.

- Electrical design (EPLAN P8)

- Creation and adaptation of software for B&R controllers

- Supportive commissioning

Technologies (excerpt):

- B&R control systems for measuring power and recording measurement values from external sensors for various drilling devices

- Visualization for entering test parameters and displaying results

The projects mentioned above are just a selection from the last years. We are happy to provide you with further references – please don't hesitate to contact us!

Are you looking for modern control technology solutions?

Let us convince you in a personal conversation! Arrange an appointment with us right away: