Renewal of six roller test rigs including new visualization system

Date: 2023 to 2025

Contracting entity: HORIBA Europe GmbH

End customer/site of installation: BMW Aschheim

Project description:

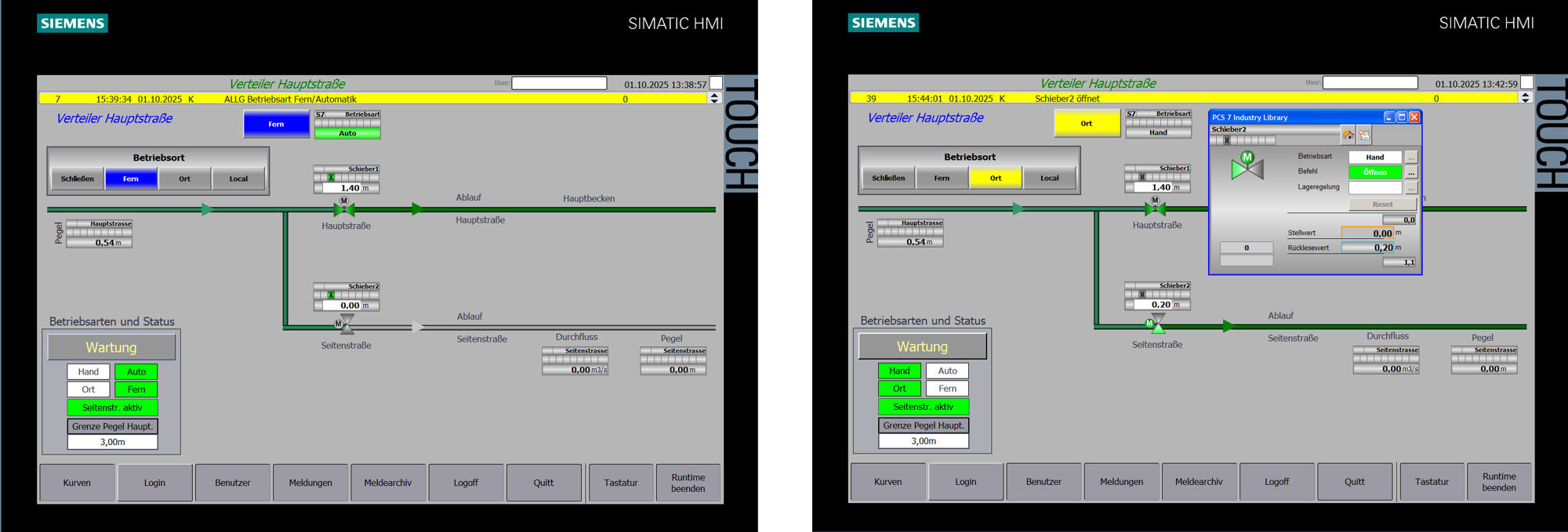

In the course of the new construction of six chassis dynamometers, we received the partial order to develop a new human interface and the visualization. The operating concept, which had become outdated, was to be renewed and converted to a modern concept with a promising future. The human interface is used for the central control and visualization of each test rig. In the first step of the project, seven human interfaces are built; in the second step, another nine are built and delivered. Visualization takes place via a server-client system with WinCC Unified V18.

- Planning (hardware construction, software project planning)

- Control cabinet construction

- Supply of new subdistribution boards, control cabinets, and human interfaces

- Assembly and installation

Technologies (excerpt):

16 pieces subdistribution boards/cabinets with S7-1516F/S7-1515F CPU | 16 pieces human interfaces with ET200SP | WinCC Unified V18 | TIA V18