Fendt MOD MO25F01

- Subline (2. Überschrift optional):

Expansion of an AGVS for integrating hybrid assembly stations for the additional production of e-tractors

Date: 2023 to 2024

Contracting entity: DS Automotion GmbH

End customer/site of installation: AGCO Fendt – Marktoberdorf

Project description:

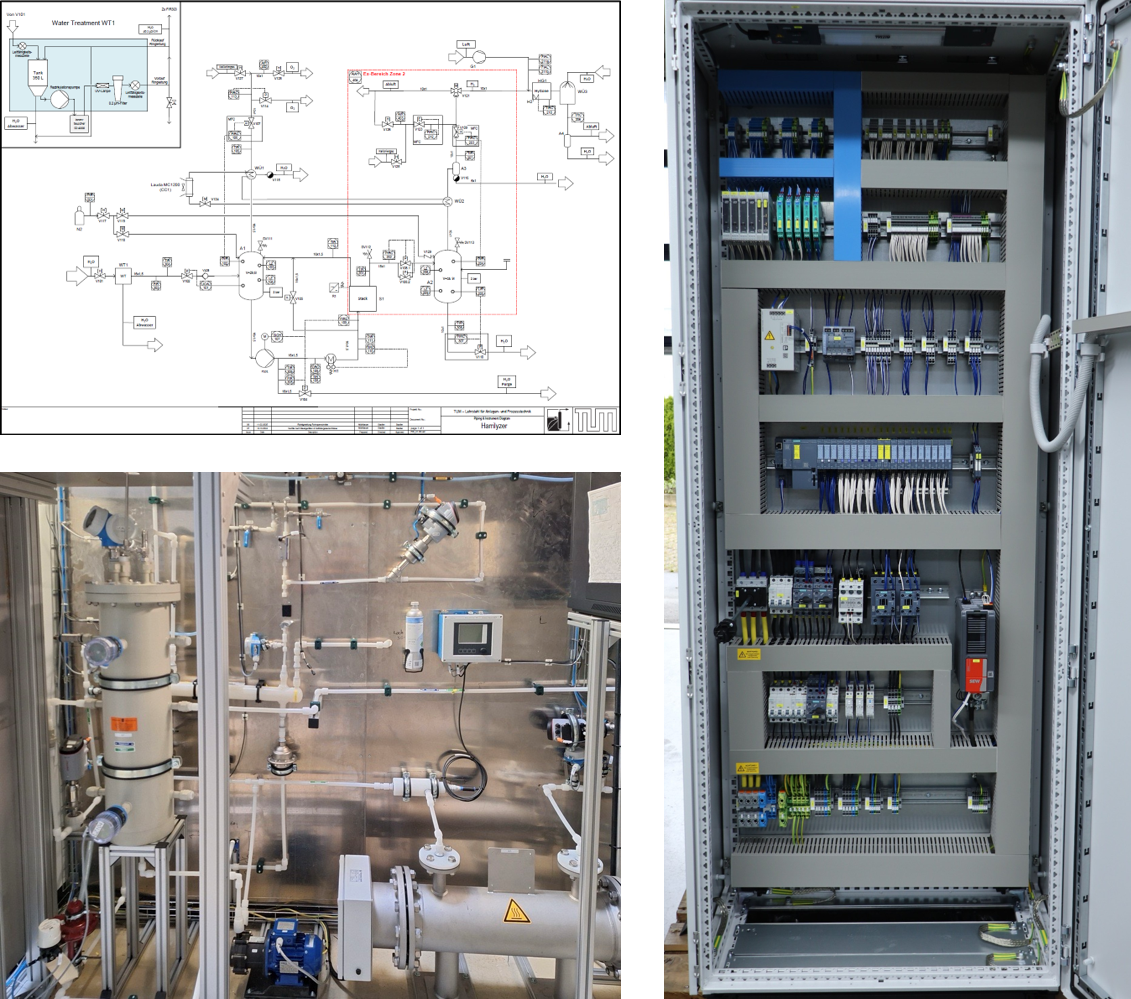

- Entire electric planning (hardware construction, software project planning)

- Extension of control cabinet construction

- Provision of control technology for the extension works

- Assembly and installation

- System commissioning

Technologies (excerpt):

S7-414F-3PN/DP | 4 pieces MP277 10" TOUCH | 10 pieces access points for Wi-Fi coverage (communication with vehicles) | 30 pieces vehicles for transport and setup of the tractors (combustion engines and e-tractors)

Process description:

The assembly line was adapted for the integration of the new electric vehicle (E124P series) into the final assembly of tractors in Marktoberdorf. The automated guided vehicle system (AGVS) ejects the vehicles with bodies for electric tractors from the existing production line so that high-voltage assembly and testing processes can be carried out in a new, separate hall area before they are returned to the production line.

The central control system developed by Kocher for the AVGS carries out not only the data management with the hall control system of the end customer (order data to error messages), but also all process-relevant orders of the vehicles through the processing stations. With its own Wi-Fi communication, it is the centerpiece of the workflow and controls the process throughout the entire production line for all station control points.

Entries can be made via a visualization interface to adjust parameters, select/deselect processes, and display processes, vehicle positions, interface overviews, and error messages. In addition to the standard process sequences, emergency strategy concepts are implemented according to individual requirements.