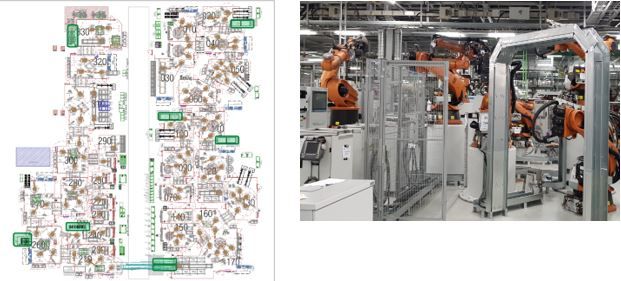

Conveyor technology with storage for wishbones and tie bar – logistics new system

Date: 2022 to 2023

Contracting entity: Esypro

End customer/site of installation: BMW Dingolfing W02.10

Project description:

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction

- Provision of control technology

- Assembly and installation

- Virtual commissioning, physical system start-up

A conveyor system was installed to supply the wishbones and tie bars to the axis production assembly line. The components are hooked into workpiece carriers according to type in batch sizes at two feeding points and stored by variety in approx. 60 storage lanes. According to the current sequence, the production control system issues a call-up, whereby the components are retrieved from the storage in sequence and transported to the assembly stations via an intermediate level using lifts. After removal, the empty workpiece carriers are conveyed back to the feed stations. Data handling is realized via RFID data carriers and barcodes.

Technologies (excerpt):

S7-1500 with CPU 1518F – PN/DP | OC visualization with WinCC-TIA on Beckhoff CP3224 | SEW MOVIFIT technology version | Murr MVK I/O modules | Siemens ET200SP and ET200Pro I/O modules | Automatic barcode reader and hand scanner