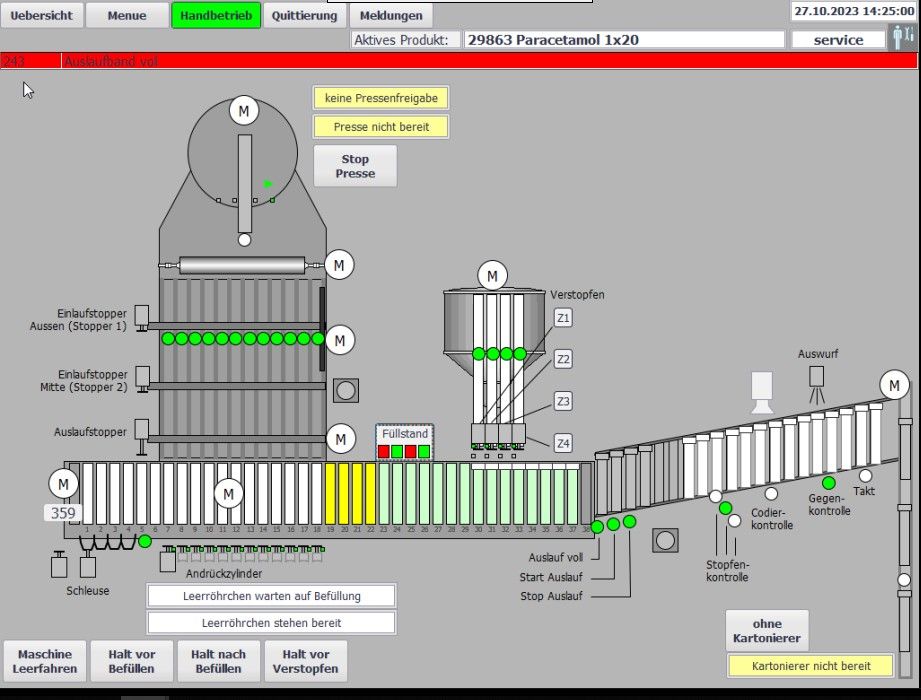

Renewal of a tube-filling system (pharmaceutical/healthcare)

Date: 2023

Contracting entity: HERMES ARZNEIMITTEL GmbH

Project description:

- Planning (hardware construction, software project planning)

- Control cabinet construction

- Supply of new subdistribution board, control cabinet, and human interface

- Assembly and installation

- System commissioning

Technologies (excerpt):

S/-1500 with CPU 1511F-1 PN | Visualization on ASEM PC HT3500 | SEW frequency converter MCX91A