Our services

First and foremost, automation stands for complexity – it describes both process and result.

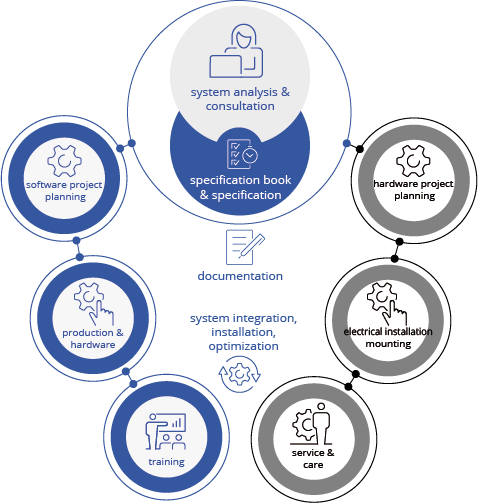

At Kocher, we therefore see automation as an endless cycle with services that continuously improve your production.

This is reason enough to regularly tailor our services to the requirements of our customers, technological developments, and, last but not least, market requirements. Here, too, we master complexity.

We set high standards for ourselves: first-class training, consulting, and support.

Every production plant or assembly line needs trained operating personnel. For this reason, we are happy to instruct your responsible employees after the successful commissioning of the control technology, if desired. Skilled technicians from our company will train your staff, laying the foundations for the efficient and safe use of your highly functional control technology. They will provide a high level of technical quality and depth that leaves no questions unanswered.

As everything is connected, you will not have to get by on your own during ongoing production. Our well-trained service staff is quick off the mark in case of an emergency and ready to support you in subsequent optimization.

Put on paper – or not? It’s your choice!

As a modern company, we know our ecological responsibility. That's why we always prepare our documentation in digital form. Nevertheless, it is sometimes necessary to provide a paper version. You can be sure to always receive all documents you need for your control technology and for the repair of parts and components – whether digitally or on paper.

We are there when you need us: system integration, commissioning, and optimization.

We master all common PLC systems, their installation, programming, commissioning, and optimization down to the very last detail. Visualizations and safety systems are our daily business. First of all, we create digital twins – that way, you can see your plant and its functionality in advance!

On request, we will check your existing systems and implement new functions and cycle time optimizations for your production during manufacturing downtimes. We have been using this approach successfully for many years when integrating control technology for industrial enterprises.

Not to forget: industrial robotics or NC/CNC manufacturing – areas in which we can operate confidently and provide quick help. When it comes to control systems, we will get the most out of your plants.

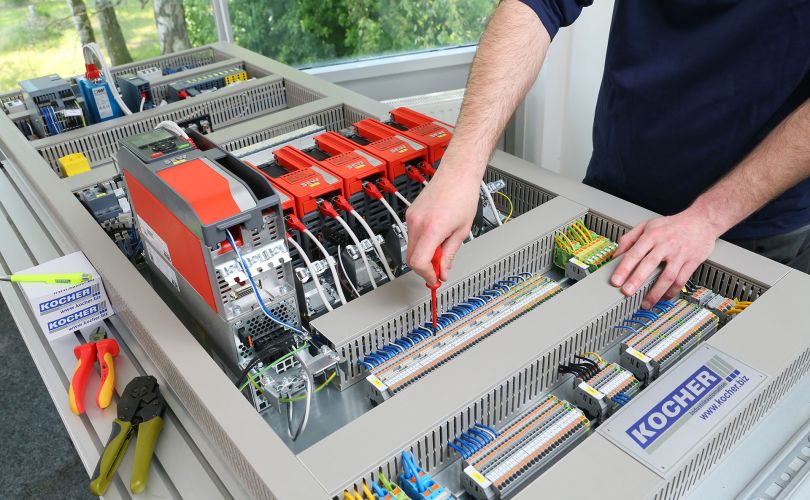

We are experts for first-class manufacturing, assembly, and electrical installation.

We make sure your mechanical plant gets a move on! Whatever we set about, we work with great skill and passion – from the electromechanical production of control cabinets to the assembly of cable ducts or shafts to various sensors and actuators for your machines and systems.

Whenever solid electromechanical work is involved, we set the bar very high and thus lay a really secure foundation for the reliable and long-term operation of your (new) control technology.

This is where our passions team up.

After discussing your specifications, we start planning the hardware and software projects. Our focus: to meet your requirements according to the latest technical standards.

In the first step, we consider your specifications from a control technology perspective. Who has to communicate with whom and what should be the result? Once these questions have been answered satisfactorily for both of us, we move from hardware to the details of software project planning. We link the topics together in a meaningful way, incorporate your existing business processes, and implement a future-proof overall solution.

You provide the system – we’ll make it move!

Listening – that is what matters. To us, it is more important than technical details before we start a project. We are therefore happy to take the time to find out everything that is important to you and has to be included in the customer requirements.

It is the conversations between your engineers and our employees that open up further topics. This technical sparring and a combination of listening, reading, asking, and specifying gradually leads to a coherent concept of your needs. This provides the basis for the overall success of your project and thus the content that absolutely must be included in the specifications.

This way, we make sure that no questions remain unanswered concerning processes, technical structure, plans, documents, or checklists, and that your engineers don’t hesitate to accept the project.

We know the right adjusting screws: system analysis and consulting.

By means of a system analysis, we can provide you with reliable statements on the control technology of your plant and identify optimization potential.

Thanks to our decades of experience, we assess the overall plant effectiveness of a production line in the context of the control technology in use, for example.

Trust our specialists and their expertise in system analysis. Rely on our experience from countless national and international projects. Together with you, we are happy to evaluate the potential we can unlock in your production regarding plant availability, performance, or manufacturing quality.